(click on picture above to see larger version)

A lot of my projects are built around some gizmo that I run across whereby I don't have to reinvent

the marconi, yet I can risksome experimentation or a new idea because this gizmo is so dang cheap.

Such was the case with this chinese Frequency counter module for $15: the PLJ6LED Freq Meter.

Here's a microcontroller-based 6-DIGIT LED (read: bright!) Frequency Counter

for 100 KHz thru 65 MHz, including front end buffer, 8-12VDC power input, and capable of IF-Offsets.

This sounds PERFECT for a digital frequency display for a homebrew or vintage rig!

Well, perfection can always be improved upon, and I have a compulsion toward that anyway.

Here's what I was thinking:

- 6 Digits gives us 100 Hz resolution (in the display) re: 21.040.1 = 21040.1 KHz - Power from a DC voltage *** OR *** - Power from an AC filament voltage (6.3 or 12.6 VAC, as from a Vintage Tube rig) - Heck, power from either one... - nice package that would look good with either vintage or modern equipment

(click on picture above to see larger version)

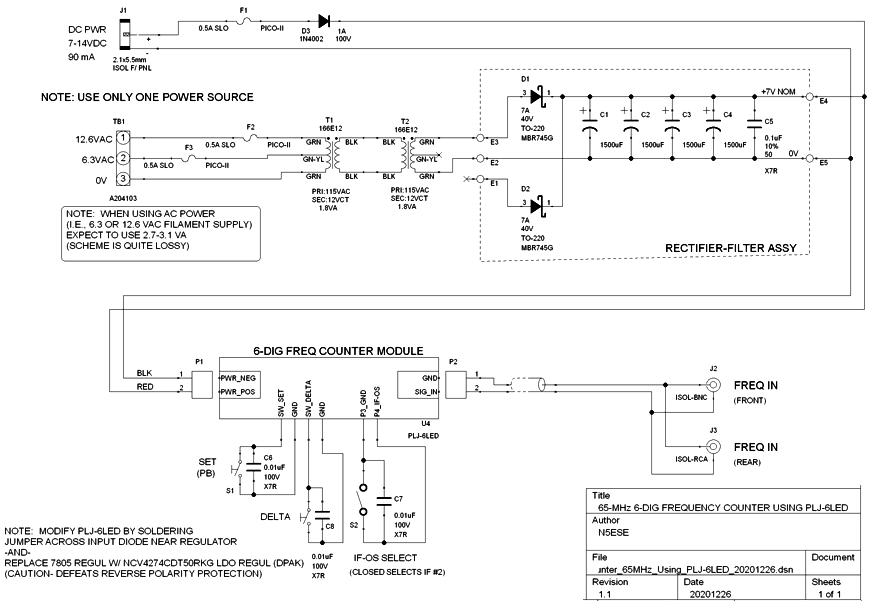

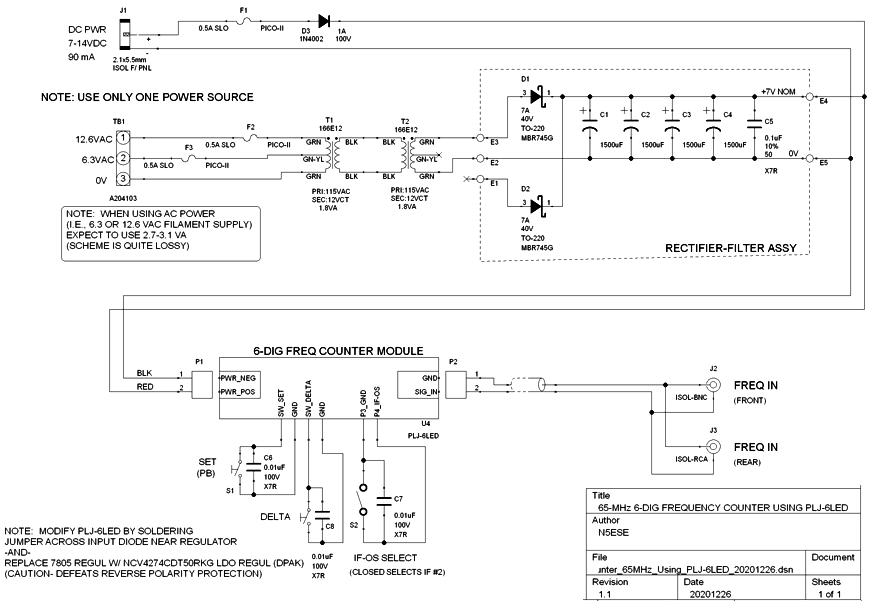

Because almost all the functionality is contained in our chinese PLJ6LED Freq Counter,

there's not a whole lot to see here. The module needs three switches: two pushbuttons

and a SPST switch. We provide a cable from the front/rear panel BNC connector (in

parallel) to the signal input on the PLJ6LED module (we call that "F-IN").

We must also provide power to the module. Originally, the module called for 8-12VDC, but

we modified the module to replace the old-technology 7805 (5V Regulator) with a Low-Drop-Out

(LDO) NCV4274CDT50, which now allows us the luxury of expanding out input voltage to 7-14 VDC

at the 2.1x5.5mm Input Jack. While a switcher can be used, a power adapter using a

linear regulator would probably give better performance in an RF environment. Expect

90mA typical, but allow for double that.On the bench, I'll often use a 9.0V battery pack

for this, especially if it's just for a short measurement or test.

OK, so now comes the ~~~wEirDneSs~~~ the two back-to-back filament transformers.

Huh?

Old-timers will be nodding knowingly right about now, but most of you are probably wondering

if I've been sucking solder smoke a few too many years. (probably a reasonable surmise).

The transformers are two identical 1.8VA (very small) filament transformers having a nominal

output of 12V center-tap at 0.145 mA. Putting them back-to-back provides isolation,

but that's only a small part of the objective. As shown, the 115 VAC side of each

transformer (normally, the primary) are connected together. If we apply 12.6VAC across

the left winding of T1, then the other side will be in the vicinity of 115 VAC. That

is applied to the Primary of T2, which outputs 12.6VAC on it's secondary, and which then feeds

the rectifier/filter. Why would we do that?

Well, maybe we don't have 12.6 VAC filaments on our vintage rig. Maybe we only have 6.3 VAC.

So with this scheme, we can instead provide T1 (left) with 6.3VAC across just one side of

T1 (to its center-tap). All other things being equal, we'll again have 115VAC on the

output side feeding the primary of T2. And so, once again we have 12.6VAC on its

secondary.

So with this scheme, we can use the filament output (usually on an accessory connector) of

a vintage tube rig to power our digital Frequency Display. Sometimes that will be 6.3 VAC,

and sometimes that will be 12.6 VAC (depends on the vintage rig). We'll take either

one, because we have our weird (but oh-so-clever) back-to-back filament transformers.

It's not without a downside. The back-to-back transformer arrangement has quite a bit of

power loss, and we'll have to supply some extra power at the filament input than we

would by supplying DC power directly. Probably, about twice the power. But still no

more than a typical extra tube filament that might be supplied by that vintage accessory

socket to a tube-type accessory of vintage origin. So it all works out, and using the

vintage filament power, we won't need to find an extra AC Power Outlet.

We wanted this to look nice enough to sit on top or to the side of the vintage rig.

Note: to the side will have less heat, and probably be preferable - vintage rigs can sometimes get

quite hot on top!

We selected a 4.7"L x 3.2"W x 2.2"H Hammond 1590TBK, a die-cast aluminum box with a black

powder-coat finish. There's quite a bit of drilling and filing to do, what with the

6-Digit display and BNC holes, but it's all do-able, with care and patience.

We also mount the rectifier/filter components on a small perf board, which then mounts on

one "side" of the diecast box, on short standoffs. Theree are a few other dialyl

(insulated) standioffs here-and-there, to facilitate wiring.

We mentioned mods to the PLJ6LED module. Here is that summary:

Modifications Required to PLJ-6LED Module:

1. Place Jumper across Input Diode (now, no reverse polarity protection)

2. Replace 7805 (DPAK) with NCV4274CDT50RKG (LDO Regulator, DPAK)

3. Tack wires to two onboard PushButtons, to allow front panel PB switches

4. Attach wires to Pin 3 (GND) & Pin 4 (IF SEL), to allow front panel

toggle switch selection of IF#1 or IF#2 (SPST, Short selects IF#2)

Here are some pictures of the finished construction:

(click on picture above to see larger version)

(click on picture above to see larger version)

(click on picture above to see larger version)

(click on picture above to see larger version)

I've tested this fairly throoughly, with emphasis on margin for the filament supply scheme.

You can see a report re filament power scheme - here -

The PLJ6LED module was also tested. Here's the short version:

20201207/mdn - Testing the PLJ-6LED-H 6-Digit Frequency Counter Module (as rcvd)

- Current Consumption (while counting):

75 mA @ 13.8 VDC supply (measurewd at module input)

44 mA at 5.8 VDC supply " "

-Input Voltage (RF) for Stable Readings:

- 30 mV-rms @ 32 MHz

- 200 mV-rms @ 80 MHz

- Temperature: After 30 min, no component on board was more than fingers-warm

Note 1: unreliable above 80 MHz

Note 2: Subject to stray noise, including radiated noise - needs

an RF-tight box & good power decoupling

Note 3: IF Offset Operation not checked

Note 4: Oscillator Trimmed to 10.000.0 using GPS Disciplined Osc

While I have not actually used the IF offset feature yet, I have no reason to think it does not work.

A very helpful user manual (verify it applies to the model you procure) can be found - here -

and DL7MAJ has a useful "how to" document available - here -

The front panel IF-A/IF-B switch can be very helpful in cases where some bands count up and some

bands count down (not an infrequent case in vintage rigs).

When sampling a vintage VFO (to supply signal to input F-IN), take the sample at a

low-voltage point, if possible (like the cathode of a cathode follower buffer). Be sure to use a

coupling capacitor - as small as you can get away with and still get reliable readings

at the highest & lowest frequency to be measured. Almost certainly, this will be less than

100pF, but I would start even lower, like 15pF or 20pF. Be sure that the voltage at the

far end of the cables is less than 5V pk-pk (check before connecting, using an oscilloscope

or RF peak-reading probe) so that you don't smoke the PLJ6LED module's front end. Make sure

that capacitor is rated for full DC+AC voltage, plus at least 100% margin. Use a shielded

cable - RG-58 is good - and keep it as short as practical so that it does not load your VFO (or

whatever oscillator you're monitoring). If the sample point you selected causes drift

in the oscillator, choose another tap point or add a buffer stage (or just live with it).

73,

Monty N5ESE

dit dididit dit