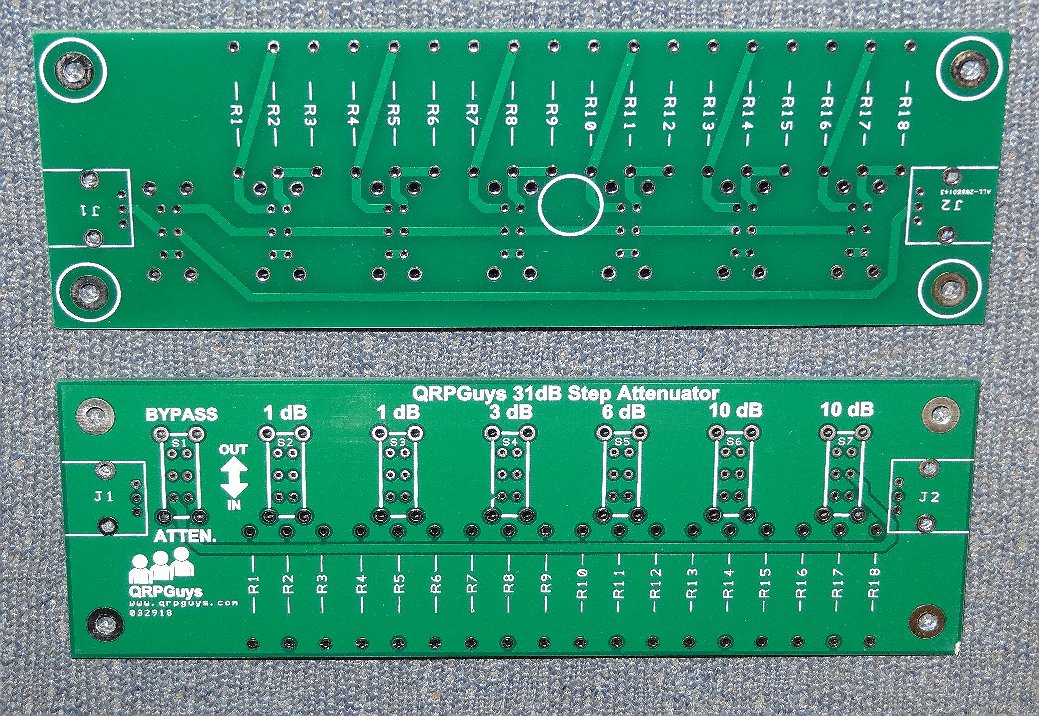

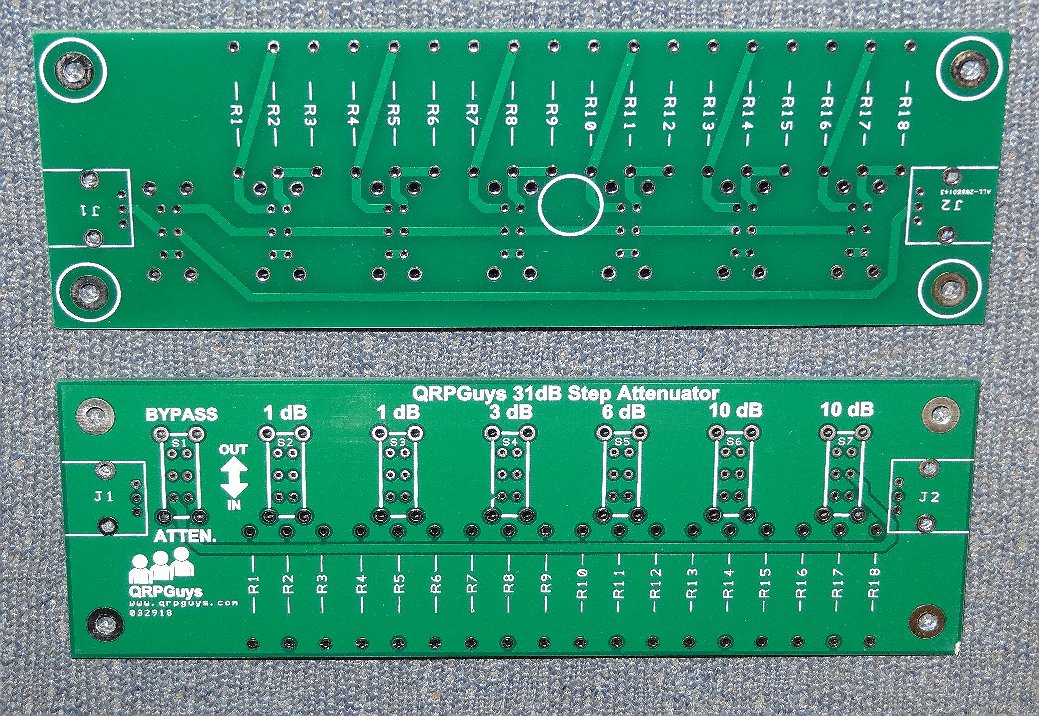

...bare board (both sides shown)

...bare board (both sides shown)

This describes a 0-31dB Step Attenuator (1 dB steps) capable of 5 Watts dissipation. It can be

used as any step attenuator might be (as a piece of test

equipment), but because it can

dissipate some power, it can be used inline with a QRP transmitter to reduce the power to the

antenna in 1-dB steps. I've had some memorable 2-way QRP QSOs by using an antenuator like this.

Each 3-db step epresents a reduction in signal to the antenna of 1/2-power. So a setting of 30dB

while running 5 watts from the transmitter results in 5 milliwatts to the antenna (and by-the-way

with a very good match, as seen from the transmitter). You'd be amazed what you can do with 5 mW

of power.

Step attenuators are used all over the workbench for various tests, but most readily available

commercial step attenuators can only handle 1/2, 1, or 2 watts. This will handle 5 watts CW and

10-12 watts SSB (PeP). So coupled inline with a CW or SSB QRP transmitter and antenna, it can be

used in 1 dB steps to reduce power to the antenna. How far can you QSO with 500 mW, 50 mW, 5 mW,

or even 1 milliWatt? You might be astonished!

It can even be used as a super-crude matchbox for the transmitter-to-antenna. For example, by

inserting 3 dB between the transmitter and most any antenna, you can be assured of two things:

- Power delivered to the antenna system will be about 1/2 of the input power

- Your Transmitter will see a load impedance of 25-100 ohms worst case, representing an SWR of 2:1 or better (most transmitters will tolerate a 2:1 SWR).

We started with a QRPGuys 0-31dB Attenuator Board-Only Kit. The full kit has been retired,

but the PCB is may still be available. We wanted to use our own switches, and our own box, and 1%

resistors, so we ordered all the rest of the ancillary stuff online.

The original pdf manual can be found - here - and you can draw the parts list (or make

substitutions) from that. We decided on Metal Film 1% 3W resistors (wherever we could get them)

instead of the 5% 3W MOX resistors QRPGuys used, because they don't cost much more, and they will

be a smidgeon more predictable and stable. Many of these, I already had in my own stock. We

checked the values before installing, and made sure all were within 1%. CAUTION Some

precision resistors are wire-wound, so be sure to select metal film or metal-oxide, because we

really don't want the inductance of a wire-wound resistor to affect the attenuation and frequency

response.

For the enclosure, we used a Hammond 1590P1 diecast aluminum box. It's just a smidgeon short for

the PCB we got from QRPGuys, so we cut off about 1/4 inch (on one end of the PCB) on the

side that had the bypass switch (which will still work). We'll used short wire jumpers to get the

BNC's where they need to go after the hack job.

We'll mount the resistors on the opposite side of the board from their silkscreen, because that

works better for our die-cast box installation and heat dissipation inside the box.

Instead of the original slide switches, we'll use a good quality 250VAC DPDT mini-toggle (Nidec

p/n 8J2011-Z) with silver contacts rated at 3A. We need 7 of them, including the Bypass switch.

We will have to solder a short bare-wire jumper at each switch terminal, as the spacing between

terminals is not quite the same as with the original slide switches.

Here are some pix (click on any picture to see larger image):

...bare board (both sides shown)

...bare board (both sides shown)

Note: Two PCBs are shown above (so that I could show both sides, including

silkscreens). But only one PCB is needed.

...box drills and BNC mounting

...pcb shortened (left side), resistors mounted

...toggle switches mounted but not soldered (opposite side from resistors)

...resistors and switches (side view)

...inside view (all components mounted)

I've used this a number of times on-the-bench and on-the-air. It does the job very nicely at QRP 5W.

73,

Monty N5ESE

dit dididit dit